The Key to Efficient Battery Operation:Effective Liquid Thermal Management

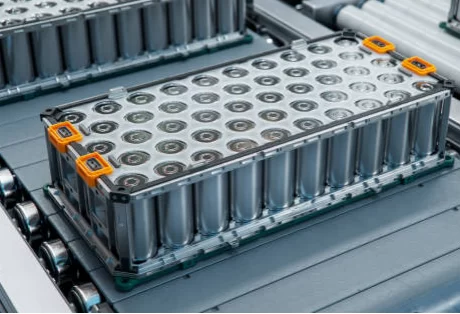

In today’s rapidly evolving technological landscape, batteries have become an essential component in a wide range of applications, from portable electronics to electric vehicles and renewable energy storage systems. As the demand for high-performance batteries continues to grow, so does the need for efficient battery operation. One of the key factors in achieving efficient battery operation is effective liquid thermal management.

In today’s rapidly evolving technological landscape, batteries have become an essential component in a wide range of applications, from portable electronics to electric vehicles and renewable energy storage systems. As the demand for high-performance batteries continues to grow, so does the need for efficient battery operation. One of the key factors in achieving efficient battery operation is effective liquid thermal management.

Batteries generate heat during operation due to internal resistance and chemical reactions. If this heat is not properly managed, it can lead to a number of issues that can negatively impact battery performance and lifespan. High temperatures can cause the battery’s internal chemistry to degrade, reducing its capacity and increasing the risk of thermal runaway. Additionally, uneven temperature distribution within the battery can lead to inconsistent performance and reduced overall efficiency.

Effective liquid thermal management offers several advantages over traditional cooling methods. Liquids have a higher heat capacity than air, meaning they can absorb and transfer more heat. This allows for more efficient cooling of the battery, even under high-power operating conditions. Liquid cooling systems can also be designed to provide more uniform temperature distribution within the battery, reducing the risk of hot spots and improving overall performance.

One of the most common types of liquid cooling systems for batteries is direct liquid cooling. In this approach, a coolant is circulated directly through channels in the battery pack. The coolant absorbs heat from the battery cells and transfers it to a heat exchanger, where it is dissipated to the environment. Direct liquid cooling can provide very efficient cooling, but it requires careful design to ensure proper sealing and prevent coolant leakage.

Another approach is indirect liquid cooling, where a heat exchanger is used to transfer heat from the battery pack to the coolant. This method is less complex than direct liquid cooling and reduces the risk of coolant leakage, but it may have slightly lower heat transfer efficiency.

In addition to providing efficient cooling, liquid thermal management systems can also be integrated with other battery management functions. For example, temperature sensors can be used to monitor the temperature of the battery cells and adjust the cooling system accordingly. This can help to optimize battery performance and extend its lifespan.

The design of an effective liquid thermal management system requires careful consideration of several factors. First, the choice of coolant is important. Coolants should have a high heat capacity, low viscosity, and good thermal conductivity. They should also be chemically stable and compatible with the battery materials. Common coolants used in battery cooling systems include water-glycol mixtures, dielectric fluids, and phase change materials.

Second, the design of the cooling channels and heat exchanger must be optimized to ensure efficient heat transfer. This may involve the use of computational fluid dynamics (CFD) simulations to analyze the flow of coolant and heat transfer within the system. The size and shape of the cooling channels, as well as the location and configuration of the heat exchanger, can all have a significant impact on the performance of the cooling system.

Finally, the control strategy for the cooling system must be carefully designed to ensure that the battery operates within a safe temperature range. This may involve the use of temperature sensors and feedback control algorithms to adjust the flow rate of the coolant or activate additional cooling measures if the temperature exceeds a certain threshold.

In conclusion, effective liquid thermal management is a key factor in achieving efficient battery operation. By providing efficient cooling and uniform temperature distribution, liquid thermal management systems can help to improve battery performance, extend its lifespan, and reduce the risk of thermal runaway. As the demand for high-performance batteries continues to grow, the development of advanced liquid thermal management systems will become increasingly important. With careful design and optimization, liquid thermal management has the potential to revolutionize the way we power our devices and systems.