Current Status and Comparison of Battery Energy Storage Technologies: An Insight You May Not Know!

1. Lead-Carbon Batteries: The Short-Term Cost-Performance Champion

Lead-acid batteries are the most commonly used energy storage technology. They are affordable, safe, and reliable, which are well-known advantages. However, their low energy density, short lifespan, and inability for deep discharge limit their broader application potential.

Lead-carbon batteries, on the other hand, are a different story. As a representative of advanced lead-acid battery technology, they have significantly addressed the shortcomings of traditional lead-acid batteries. In the fields of energy storage and high-performance electric vehicles, lead-carbon batteries offer much better performance indicators such as charging/discharging power, cycle life, and charging speed, with only a slight increase in production cost compared to traditional lead-acid batteries.

When compared to mainstream electrochemical energy storage technologies like lithium-ion batteries, lead-carbon batteries have a clear cost advantage in the short term. However, their discharge depth typically ranges between 40% and 60%, while lithium-ion batteries can achieve over 80%. Additionally, their high-power discharge capability is weaker than that of lithium-ion batteries. In the long run, the continued development and cost reduction of lithium-ion batteries and other electrochemical storage technologies may put pressure on the market potential of lead-carbon batteries.

2. Lithium-Ion Batteries: Rapid Growth in Industrial Development

Lithium-ion batteries are widely used due to their high energy density and fast charge-discharge rates. In recent years, their scale and technological advancements have skyrocketed. In global megawatt-level electrochemical energy storage projects, lithium-ion battery installations account for 65% of total capacity. In China, projects like the Zhangbei Wind-Solar Storage Demonstration Plant, Shenzhen Baoqing Energy Storage Plant, and Jiangsu Zhenjiang Energy Storage Project have all adopted lithium-ion batteries as their core technology.

Why is lithium-ion technology developing so quickly? This can largely be attributed to the increasing demand for electric vehicle batteries, which has accelerated the lithium battery industry’s progress. The economies of scale for lithium-ion batteries in energy storage are becoming evident, leading to a sharp decline in costs. For instance, the cost of lithium iron phosphate batteries, widely used in energy storage, has dropped from around ¥4500-6000/kWh in 2013 to as low as ¥2000-3000/kWh after 2015, with costs continuing to decrease in recent years.

Additionally, the secondary use of lithium-ion batteries further enhances their cost-effectiveness. Once their capacity drops to 80%, they are retired from electric vehicle use but remain valuable for energy storage applications. Countries like the U.S., Germany, and Japan, which began exploring secondary use earlier, have already achieved successful results. With the increasing number of retired batteries from electric vehicles in China, and the improvement of secondary use technologies and industrial chains, the cost of lithium energy storage is expected to decrease further.

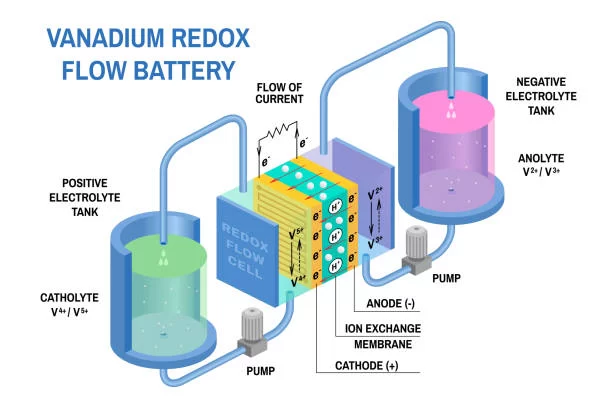

3. Vanadium Redox Flow Batteries: Longevity is Their Highlight

There are various types of flow batteries, known for their excellent charge-discharge performance, long cycle life, and adjustable power and capacity, making them particularly suitable for large-scale energy storage. Among them, vanadium redox flow batteries are the most widely used technology. These batteries can achieve over 10,000 charge-discharge cycles, with independent power and capacity systems, and the ability to restore capacity online.

However, vanadium redox flow batteries have their drawbacks. Their cost per kilowatt-hour is 2-4 times higher than that of lead-carbon and lithium-ion batteries, leading to high initial investment. Nevertheless, considering their cycle life, which is 2-3 times longer than lead-carbon and lithium-ion batteries, their cost per cycle can still be competitive. Other limitations include an energy conversion efficiency of around 70%, low energy density requiring more land and building resources, and operational complexity due to auxiliary equipment like electrolyte circulation pumps.

4. Sodium-Sulfur Batteries: Dominated by Foreign Technology, Domestic Challenges Persist

Sodium-sulfur batteries have high energy storage capacity, stable operation, minimal maintenance requirements, and a cycle life of over 4000 cycles. They also have over a decade of proven operational performance. However, these batteries require a high operating temperature of 300℃-350℃, which poses certain safety risks.

While sodium-sulfur batteries have matured abroad, with over 200 storage plants built globally—second only to lithium-ion batteries—the technology remains monopolized by Japan’s NGK. This company leads globally in sodium-sulfur battery system development and is the only enterprise capable of large-scale commercial production. In contrast, China’s research and development in this field started late, making short-term commercial promotion challenging.

Each energy storage battery technology has its strengths and weaknesses. Lead-carbon batteries offer high cost-performance in the short term, making them suitable for applications sensitive to costs but not demanding deep discharge or high-power output. Lithium-ion batteries, with their scale advantages and secondary use potential, are the frontrunners in energy storage, offering broad application scenarios. Vanadium redox flow batteries, with their long cycle life, are ideal for large-scale energy storage despite high initial costs and operational challenges. Sodium-sulfur batteries boast high performance but face constraints from high operating temperatures and foreign monopolization.

In the future, energy storage development will require careful consideration of these factors to select the most suitable battery technology for specific needs. Meanwhile, continued advancements and breakthroughs in research and application are anticipated to drive the energy storage industry toward greater innovation and growth.